A VRF system (Variable Refrigerant Flow) is a type of advanced HVAC (Heating, Ventilation, and Air Conditioning) system that provides efficient and flexible climate control for commercial and residential buildings. Here's a breakdown of how it works:

🔧 Basic Concept

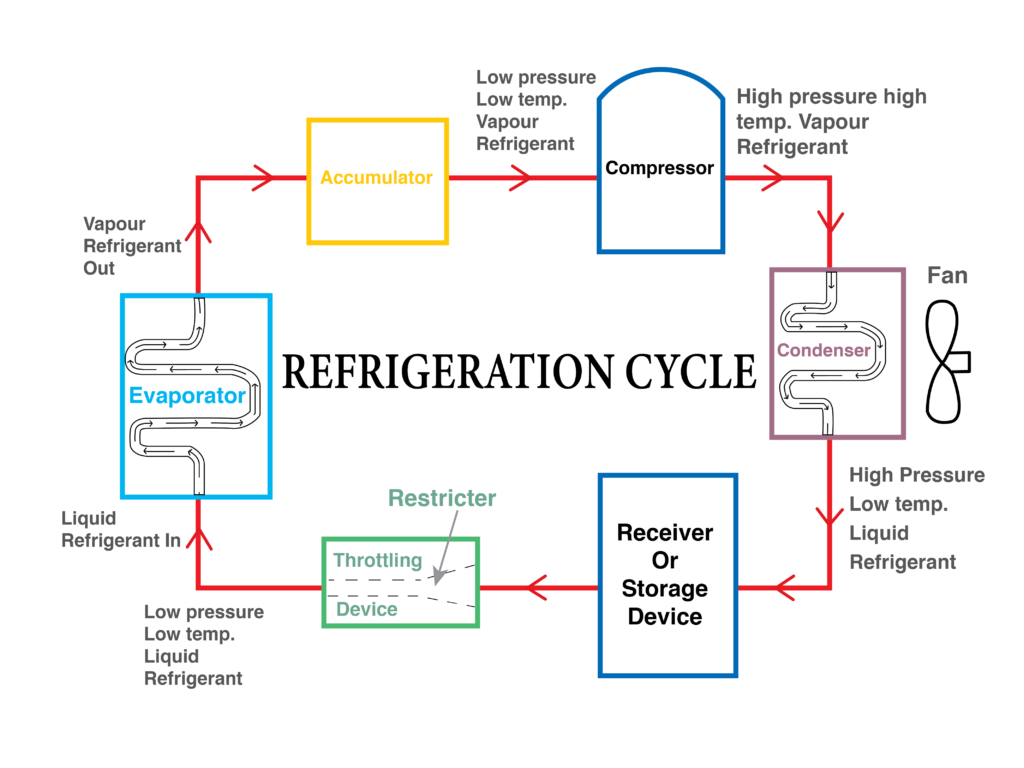

VRF systems use refrigerant as the cooling and heating medium, which is conditioned by one or more outdoor condensing units and circulated within the building to multiple indoor units.

⚙️ Key Components

-

Outdoor Unit (Condenser)

-

Contains the compressor(s) that vary the refrigerant flow.

-

Connected to multiple indoor units via refrigerant piping.

-

-

Indoor Units (Evaporators)

-

Come in various types: wall-mounted, ceiling cassette, ducted, etc.

-

Can be independently controlled for individual zones.

-

-

Refrigerant Piping Network

-

Copper pipes carry refrigerant between the outdoor and indoor units.

-

Often a 2-pipe or 3-pipe configuration (depending on the system type).

-

-

Control System

-

Centralized or individual controllers manage temperature, fan speed, and mode for each zone.

-

🔄 How It Works

1. Cooling Mode

-

The compressor pumps refrigerant to indoor units.

-

The indoor units absorb heat from rooms and send the heat-laden refrigerant back to the outdoor unit.

-

The outdoor unit releases the heat to the atmosphere.

2. Heating Mode

-

The cycle reverses using a reversing valve.

-

Indoor units act as condensers and provide heat to the room.

-

Outdoor unit absorbs heat from the outside air (even in cold conditions).

🔁 Variable Refrigerant Flow

-

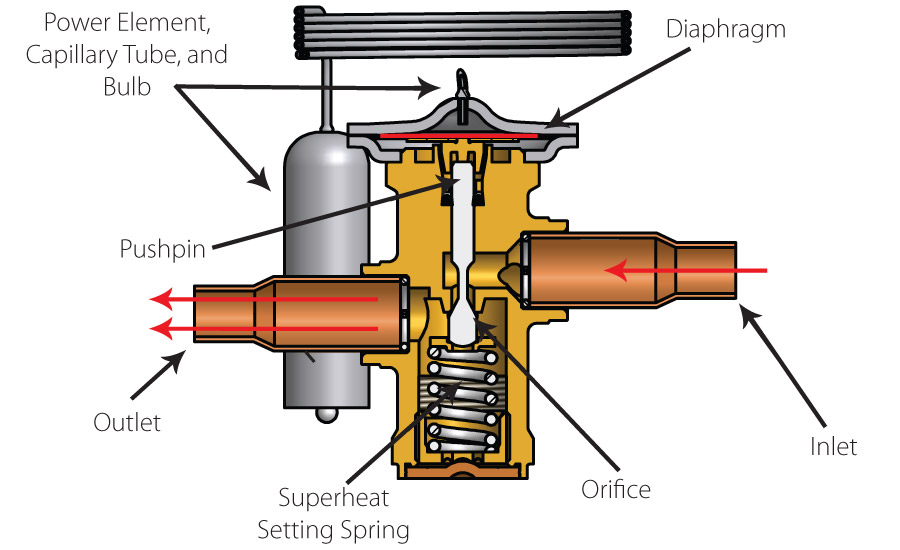

The compressor modulates its speed (inverter technology), adjusting refrigerant flow based on demand.

-

Only the needed amount of refrigerant is sent to each indoor unit, which improves energy efficiency.

🌀 Types of VRF Systems

-

Heat Pump VRF

-

All indoor units operate in either heating or cooling mode at one time.

-

-

Heat Recovery VRF

-

Allows simultaneous heating and cooling in different zones.

-

Uses a 3-pipe system and branch selector boxes to route refrigerant efficiently.

-

✅ Advantages

-

High energy efficiency (especially with inverter compressors)

-

Individual zone control

-

Quiet operation

-

Flexible design (good for retrofits and complex layouts)

-

Heat recovery options

❌ Disadvantages

-

Higher initial cost

-

More complex installation and servicing

-

Requires trained technicians for maintenance